The top-drive drilling system

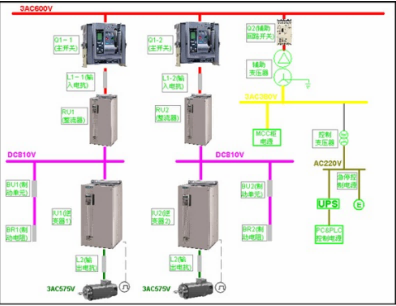

The main top drive system is an AC variable frequency system composed of two independent converters driving two 400Hp AC variable frequency motors respectively; they can jointly drive (master/slave control, SIMOLINK fiber optic communication ) or work separately.

The top-drive MCC cabinet is responsible for power supply of other auxiliary equipments of the top drive, including main motor fan, drive fan, hydraulic pump motor, cooling motor, air conditioning and lights in the electrical control room.

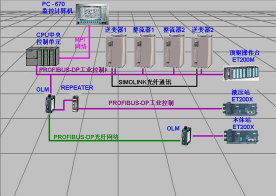

PLC is connected with control stations and drive systems through PROFIBUS-DP bus, with substations in the main body through optical fibers, and with other substations through shielded twisted pair.