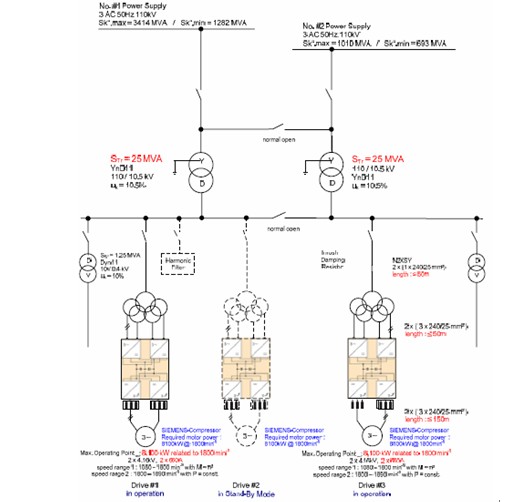

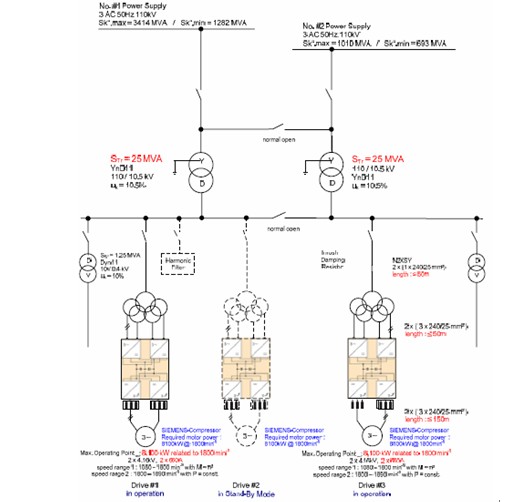

8MW Natural Gas Compressor Drive System

1. System Introduction

It is used to drive the three sets of variable frequency speed regulation system for natural gas compressor. Each system is mainly composed of:

System Diagram

System Diagram

- 3 induction motors

- 3 power converters, including:

- Oil immersed variable frequency transformer

- Control system and I/O interface

- Cooling device of converter

- Options

- 3 sets of power cable

- 3 sets of control and signal cable for the equipment room

Compressor Diagram

Compressor Diagram Drive System Diagram

Drive System Diagram2. Technical Description and Datasheet of the Variable Frequency Drive System

- 5-winding oil immersed transformer for rectifier

- For outdoor use

- 24 pulse rectifier transformer to reduce no-load loss

- High-voltage insulation class LI175/AC128kV

- Low-voltage insulation class LI240/AC220kV

- Insulation class of low-voltage system: LI40/AC10kV

- Color of enclosure: RAL7033

Datasheet of oil immersed winding transformer

- Applicable standard DINEN/IEC42504/76

- Rated capacity 9600/2x2x2,400kVA

- Rated primary voltage 10,000V

- Tapping range of adjustment ±2x2.5%

- Rated secondary voltage 2x2x2,200V

- Frequency 50Hz

- Vector group D,y4.75,d5.75,y5.25,d6.25

- System cooling: Natural oil cooling and air cooling

- Sound pressure level (1.0m)57dB(A)

- Sound power level (1.0m)72dB(A)

- Impedance voltage 4xapprox.6.5%

- No-load loss 12,500W

- On-load loss (75°C)72,000W

Datasheet of MV converter

- Quantity: 3

- Cooling method: Water cooling

- Ambient temperature 5°C till 40°C

- Altitude max.1,185 ma.s.l.

- Relative humidity in operation: Condensation not allowed

- Incoming voltage 3/PE10,000V±10%

- Frequency 50Hz±2%

- Rated converter efficiency 98.5%

- Input voltage 2x2x2.2kV

- Rated output voltage of converter

- Rated output current of converter

- Pulse count on the input rectifier side: 24

- Auxiliary power supply plus 20A pre-charging current for 25sec

- Asynchronous motor

- Three-phase induction motor of cage rotor

- Basic information of the driven device

- Driven device SIEMENS–Compressor

- Motor power 8,100kW

- Motor speed: 1080–1800rpm

- Torque in proportion to square of speed

- Speed range 1800–1890rpm

Technical datasheet of asynchronous motor

- Quantity: 3

- Manufacturer: Siemens company Loher, in Ruhstorf, Germany

- Design, tolerance and manufacturing standards

- Operating data (calculated value)

- Rated power 8,100kW

- Voltage 2×4.16kV

- Rated frequency 60.2Hz

- Rated current 2×660A

- Direction of rotation: Anticlockwise

- Oriented to the drive end of motor

- Rated torque 43,767Nm

- Power factor (P/Pn=1)0.89

- Efficiency (P/Pn=1)97.8%

- Temperature rise F/B

- Connection type: Y/Y

- Type of operation cycle S1

- Starting method: Variable frequency starting

- Speed-torque characteristic: 1M~n², square torque

- Speed-torque characteristic: 2 within 100%-105%WNn(=1800–1890min-1)

- Cooling parameters

- Cooling method IC81W

- Cooling water inlet temperature: Max. 35°C

- Cooling water outlet temperature: 42°C

- Cooling water flow approx.35m3/h

- Fouling factor of cooling water ≤0.0001m2K/W

- Bearing data

- Lubricating method: Forced oil lubrication

- Bearing type: Sliding bearing

- Oil flow per bearing: 16L/min

- Oil type VG46

- Bearing end: Cone end

- Structure type IM1003

- Type of protection II2GExpxeibIICT3(IEC60079-2)

- Protection grade

- Motor IP55

- Terminal box IP55

- Operating environment

- Operating ambient temperature -33°C up to 50°C

- Inlet oil temperature to be pre-heated up to +10°C

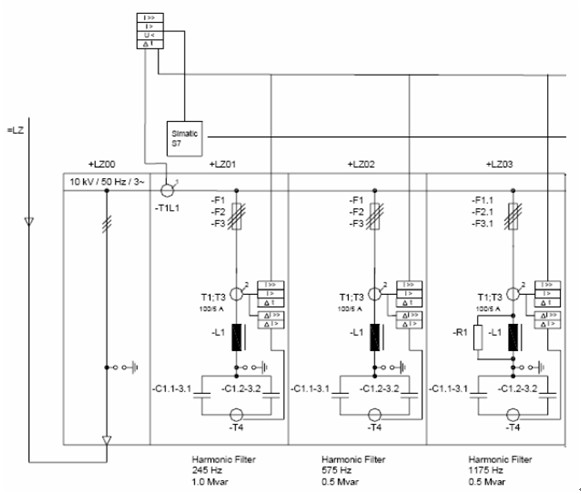

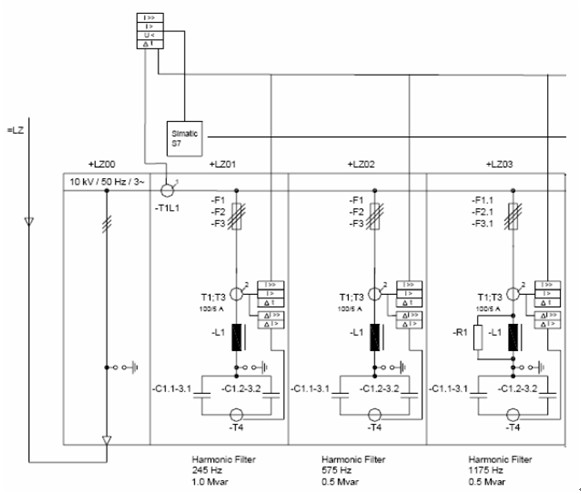

- 1 set of MV harmonic filter system

3. Single Line Diagram of Harmonic Filter System

Harmonic Filter System Diagram

Harmonic Filter System Diagram