1.Soft Pump Control System for Mud Pumps in DC Electric Drilling Rigs

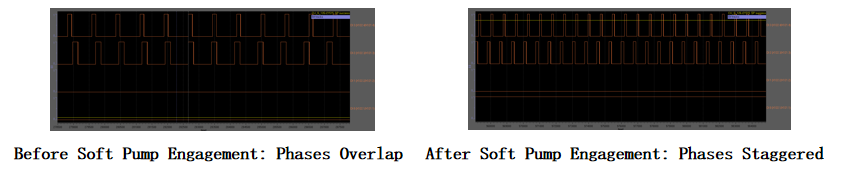

When two or three triplex mud pumps operate simultaneously, the pump strokes and phases between individual pumps are random and uncoordinated. This can easily lead to issues such as manifold resonance and interference with mud pulse telemetry signals. Currently, AC variable frequency drilling rigs have begun researching and implementing soft pump control systems, which have largely resolved these problems.However, the mud pumps on DC electric drilling rigs mostly use series-wound motors, which have more complex control characteristics.

Our company has initiated and developed a soft pump control system specifically for DC electric drilling rigs. This system can automatically adjust the pump stroke and phase of the triplex mud pumps on existing DC rigs. This results in a more uniform mud flow, effectively reduces standpipe pressure fluctuations, and solves problems like instantaneous pressure over-limits and interference with telemetry signals.

2.Direct-Drive Mud Pump and Control System Powered by Synchronous Motor

Compared to traditional DC motors, synchronous motors eliminate the need for periodic maintenance of commutators and carbon brush replacement. Unlike induction motors, they require no external excitation, offer a higher torque-to-inertia ratio, and have lower stator resistance losses. Key advantages include high efficiency across the entire power range (e.g., 97% efficiency under low load versus approximately 80% for induction motors) and a high power factor. Furthermore, the vector control system for synchronous motors enables high-precision, high-dynamic performance, and wide-range speed regulation or positioning control. In light of these advantages, our company has developed a direct-drive mud pump and its control system based on synchronous motor technology.

3.ZJ40DB Drilling Rig (New Energy) Multi-Motor Drive Control System

★Technical Approach:

1)Water-cooling technology.

2)Parallel operation of multiple small diesel generators (300KW * N units).

3)IGBT rectification and DC bus paralleling.

4)Permanent magnet synchronous motor control, leveraging standards from new energy vehicles.

5)Multi-gear coordinated control for the drawworks.

6)Power battery management and control.

★Application Benefits:

1)Reduced fuel consumption.

2)Improved diesel engine operational efficiency.

4.New direct drive agitator drive device

Utilizing variable frequency drive technology, a vertical variable frequency motor directly drives the impeller. This configuration eliminates the need for intermediate mechanical transmission components, achieving 100% mechanical energy transfer. This not only improves transmission efficiency and saves energy but also completely eliminates all associated maintenance requirements. Furthermore, for motors of the same power rating, the variable frequency motor operates with a higher power factor and a lower operating current compared to a standard motor.